During the journey from orchards to factories, walnut kernels may inadvertently carry various impurities. These "uninvited guests" not only compromise taste and quality but also pose hidden safety risks. From a scientific perspective and industry challenges, we unveil the impurities that may lurk in walnut kernels.

I. Physical Impurities: Visible Foreign Matter

1. Woody Septum

l Identity: A thin membrane inside the walnut shell, resembling the kernel in color—a master of disguise.

l Hazards: Causes a gritty texture and strongly absorbs aflatoxin (a Class 1 carcinogen), becoming a breeding ground for microbes.

l Fun Fact: Used in traditional herbal medicine for calming tea but deemed a "top adversary" in food processing.

2. Shell Fragments

l Origin: Sharp debris generated during shell-breaking.

l Risks: May injure consumers’ mouths, leading to complaints (e.g., "shell fragments found in walnut kernels").

3. Soil and Plant Debris

l Source: Dirt adhered to shells during harvesting or mixed leaves/twigs.

l Impact: Reduces product appeal; improper cleaning may introduce heavy metals (e.g., lead, cadmium).

4. Other Foreign Objects

l Members: Stones, metal fragments (from equipment wear), plastics (packaging residues).

l Threat Level: From minor discomfort to severe food safety incidents.

II. Biological Impurities

1. Insect Eggs and Larvae

l Stealth Mode: Infestation during growth; fragmented larvae remnants during processing.

l Detection Challenge: Eggs measure 0.5–1 mm, easily missed by traditional sorting.

2. Pollen and Allergens

Hidden Threat: Surface pollen from other plants risks triggering allergies.

III. Chemical Impurities

1. Pesticide Residues

l Source: Insecticides (e.g., chlorpyrifos) and fungicides used during cultivation.

l National Standard: GB 2763-2021 mandates chlorpyrifos ≤0.01 mg/kg.

2. Heavy Metals

l Soil Legacy: Arsenic, lead, cadmium absorbed via roots.

3. Oxidized Oils

Culprit: High fat content leads to peroxides (rancid odor) under poor storage.

KINGLAND——Science & Craftsmanship in Impurity Elimination

1. 17-Criteria Raw Material Screening

A stringent 17-item standard covering quality, microbial, and chemical indicators—multi-layer screening from soil to kernel.

2. Dual Shell-Breaking Methods

l Mechanical Efficiency: High-volume processing with controlled shell fragment rates.

l Manual Precision: Artisan techniques for premium kernels (e.g., baby food).

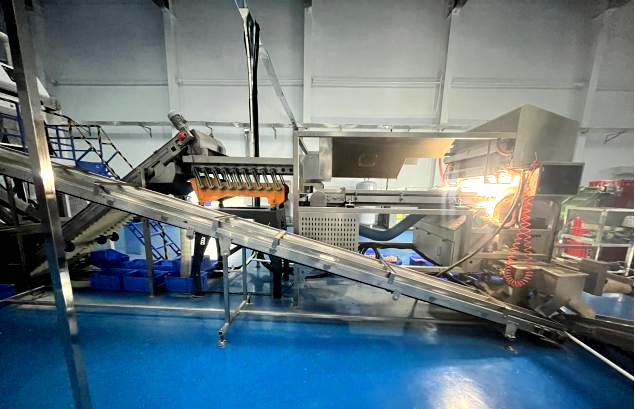

3. High-Tech Sorting for 99.999% Purity

l AI Color Sorters: Detect woody septum texture differences with 0.1 mm precision.

l Triple Sorting: Initial screening + recheck + final safeguard.

l X-Ray Detection: Identifies hollow or insect-infested kernels.

l Metal Detectors: Intercept the last metal fragment at the production line’s end.

Next time you see a pristine walnut kernel, imagine its epic "impurity purge"—from disguised woody septa to lurking aflatoxin, from clinging soil to heavy metal infiltration... The modern food industry’s mission is to make this battle silent yet thorough. As a guardian of this mission, KINGLAND is forging a secure pathway from nature to life.